Aromatic, balanced or fishy? The latter should not be the result when Karin Lamminger and her colleagues of the Sensorics Team sniff a sample glass with ethanol from the rectification plant. Instead, the alcohol must be analytically pure and as neutral as possible and “it almost always is,” says Michael Jordan, Production Master of the alcohol factory, reassuringly, who would otherwise have to pull the handbrake immediately.

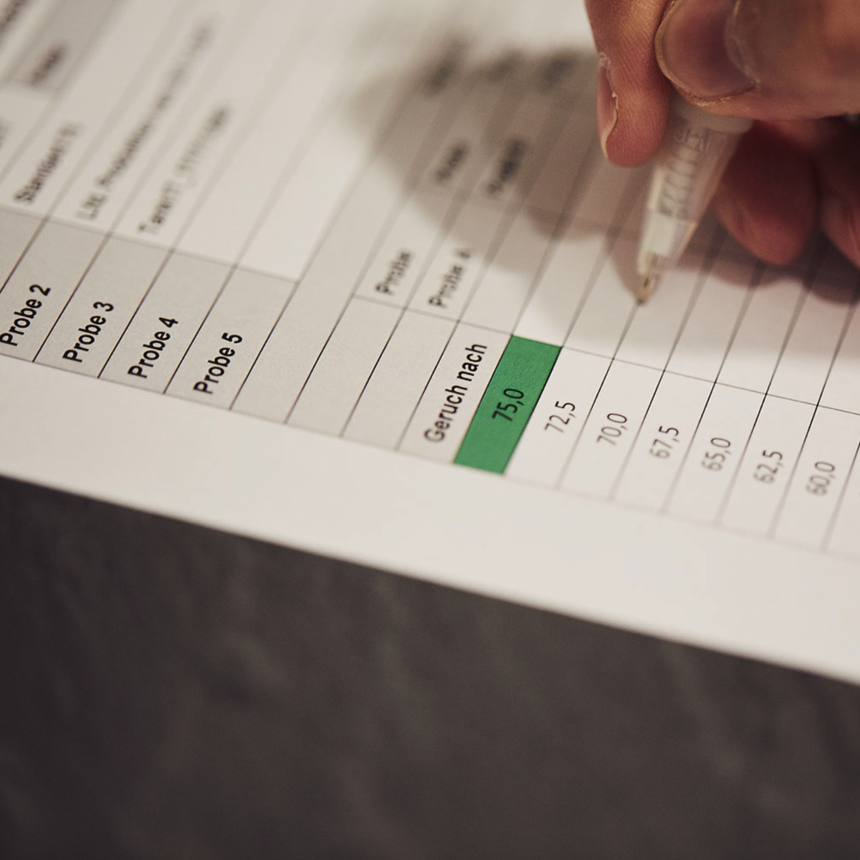

Sensor technology is a proven method of quality assurance in alcohol processing and manufacturing companies. Evaluation requires experience and an odorless environment. Sensorics at Brüggemann has its own room in which three sample glasses are waiting daily: One contains the standard, in the other, samples from the current production are waiting. 75 is the highest rating given by the Sensorics team and is mostly assigned to the standard. It has an alcohol content of up to 96.4% Vol.

Karin Lamminger has memorized the smell of the standard and can classify the other samples accordingly. Odor memory and sensitivity tests help to train the olfactory organ. Karin Lamminger knows that even if she has a bad day, machines cannot replace the human nose.